Right Angle Gear Reducers

The right-angle gear reducer is a type of gear reducer in which the input shaft and output shaft meet at a 90o angle. They are designed for efficiency, quiet operation, and long service life. The right-angle gear reducers are structured from various materials, operating speeds, and multiple ratios. The products can be used in a wide range of heavy-duty applications, including the metal industry, conveyors, etc.

HVH Industrial works with the specialized engineering teams of manufacturers to meet our customer's requirements and the highest quality standards.

If you have any questions, write us via live chat (one of our team members will answer your questions), give us a call, or send us a quote request. The HVH team is always ready to help you.

1(866)577-4040

1(866)577-4040

or

Right Angle Gear Reducers

Manufacturers

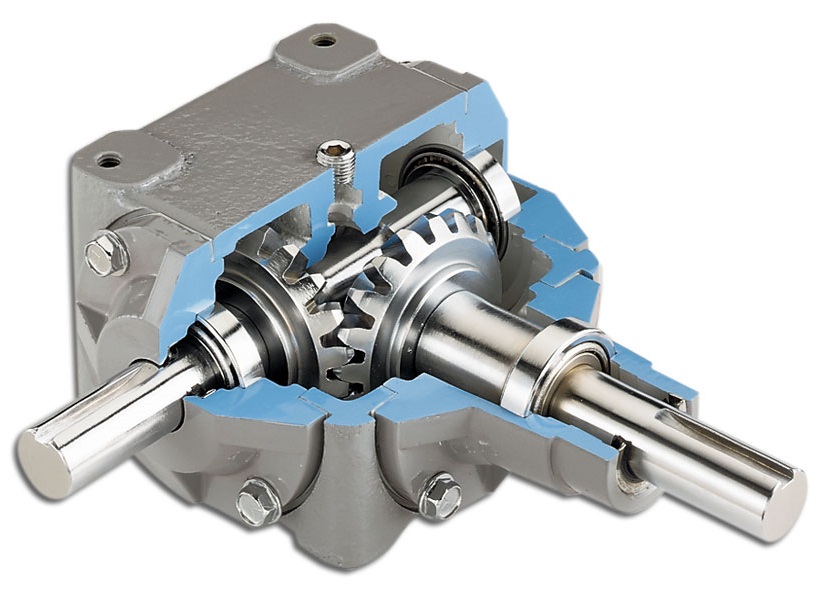

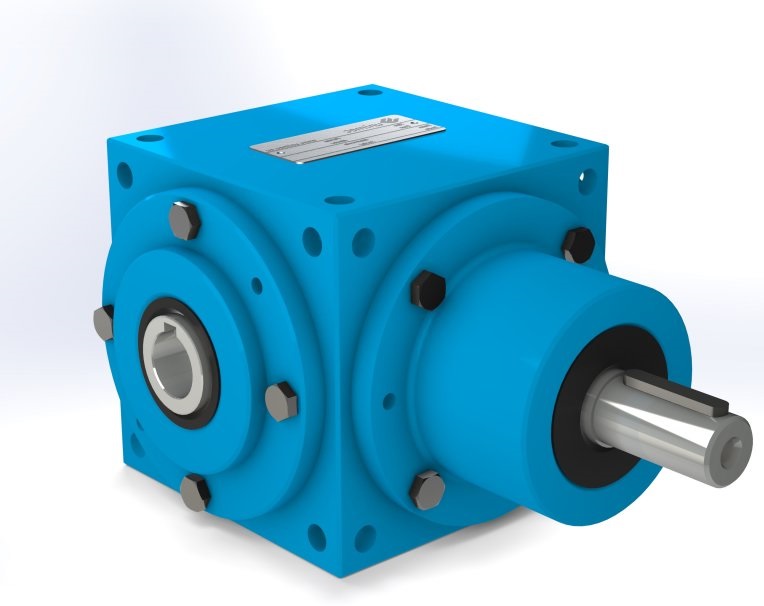

Right-angle gear reducers are mechanical devices used to reduce the speed of a rotating shaft and increase its torque output. Right-angle gear reducers are compact and designed with a right-angled configuration, and are the ideal choice for situations where space is limited and input and output shafts need to align at a 90-degree angle.

There are several types of right-angle gear reducers, most importantly worm gear reducers and helical bevel gear reducers.

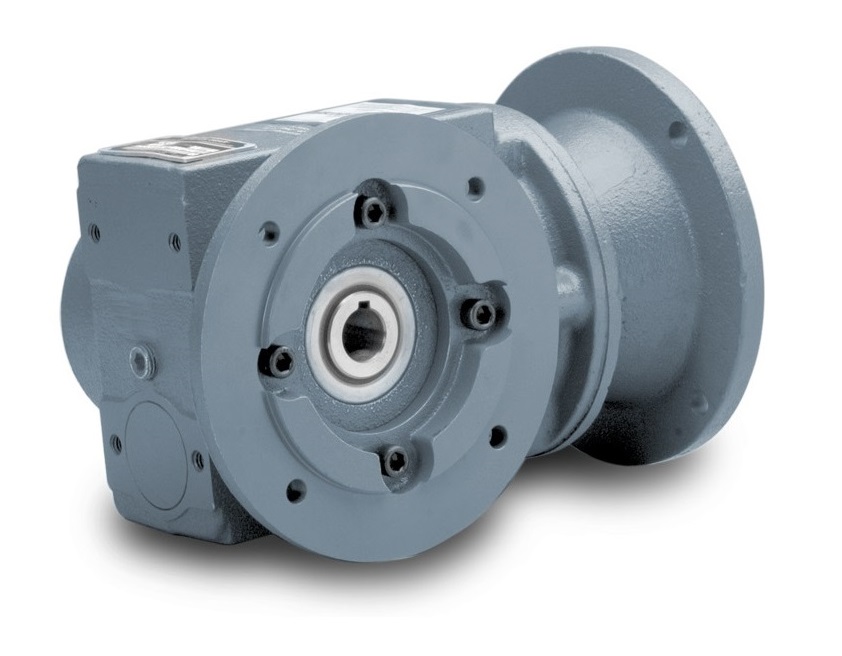

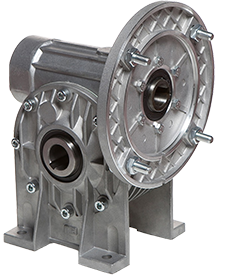

Worm Gear Reducers

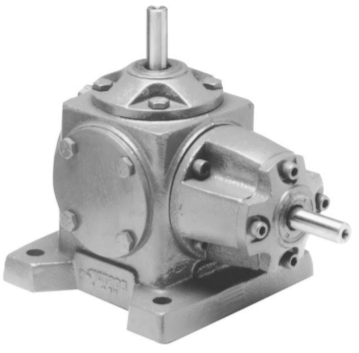

A worm gear consists of a cylindrical worm that meshes with a larger gear. The worm gear transmits power through right angles on non-intersecting shafts. Worm gear reducers, which are used to decrease input rotational speed and increase output torque, are among the most compact and least expensive options among gear reducers.

As the worm gear rotates, it exerts an axial force on the wheel, causing it to spin at a slower rate than the input shaft, which reduces the speed and torque of the input shaft, allowing it to power a variety of machinery with different speed and torque requirements.

Worm gear reducers are used in a variety of applications, from air compressors and industrial machinery to robotics and home improvement projects. They are popular for being very reliable and requiring minimal maintenance, as well as their compact size and low cost.

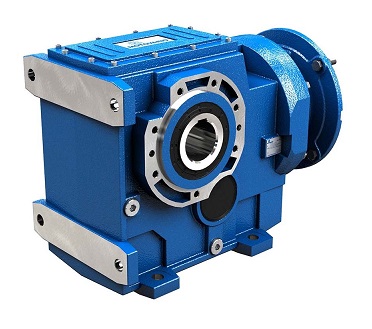

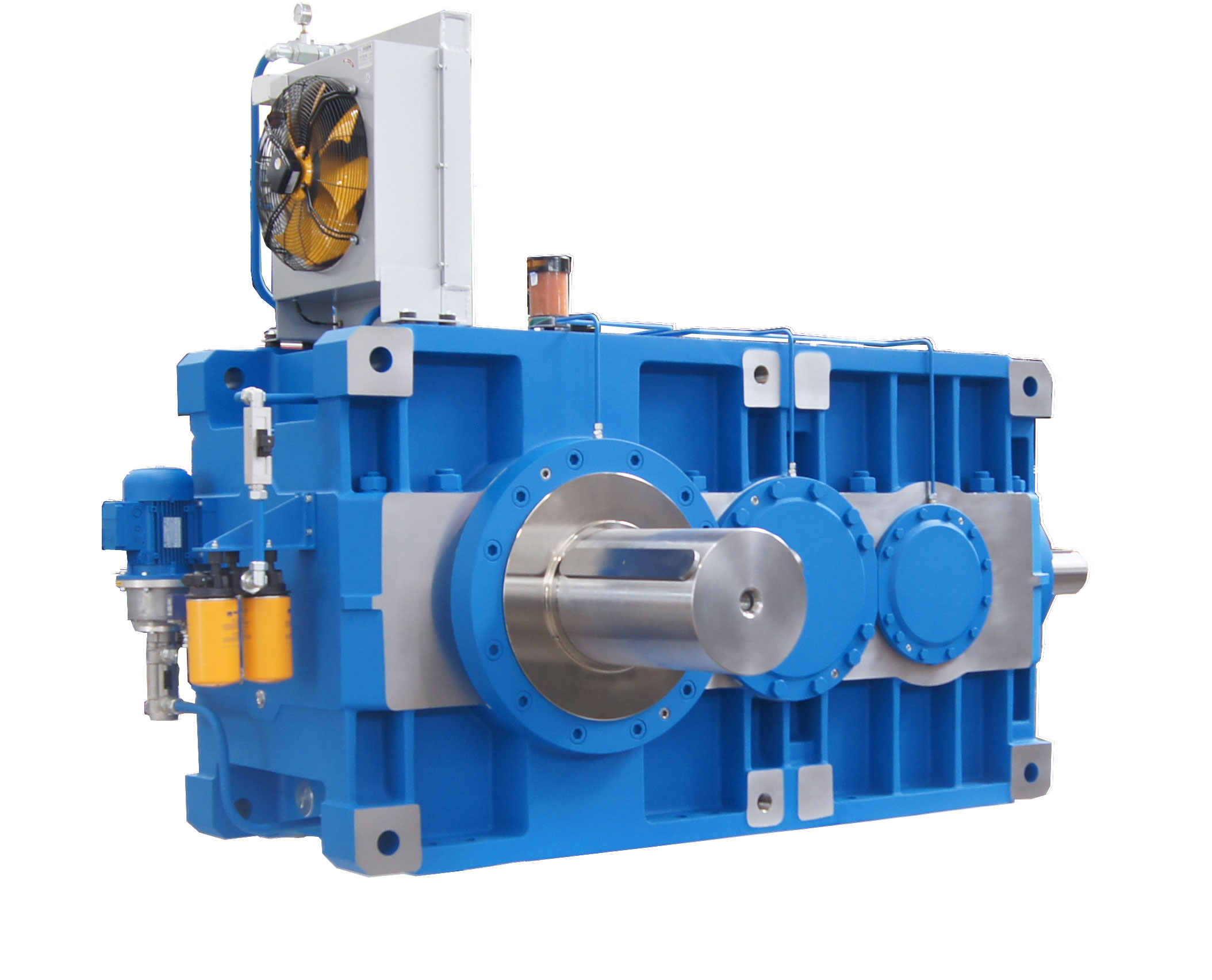

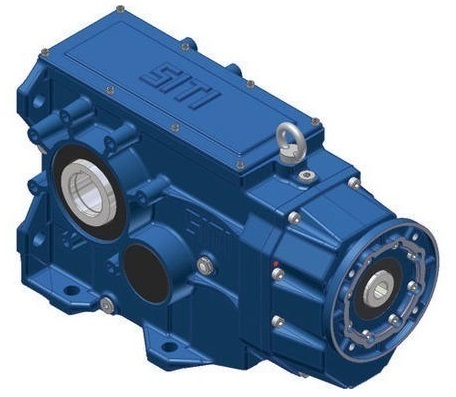

Helical Bevel Gear Reducers

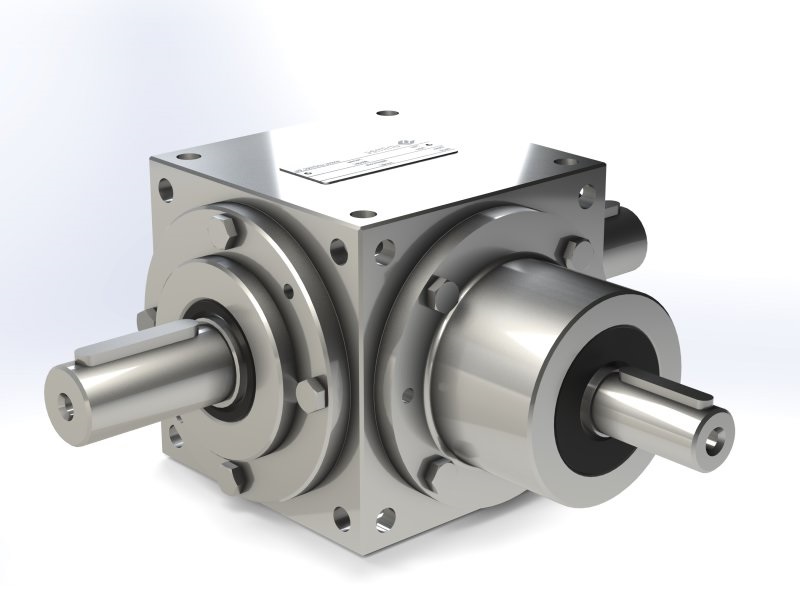

A helical bevel gear reducer is a specialized type of gearbox that uses helical bevel gears to reduce the speed of a given motor or machine and is used in several industrial applications. The teeth of helical bevel gears are slanted which makes them stronger than straight bevel gears.

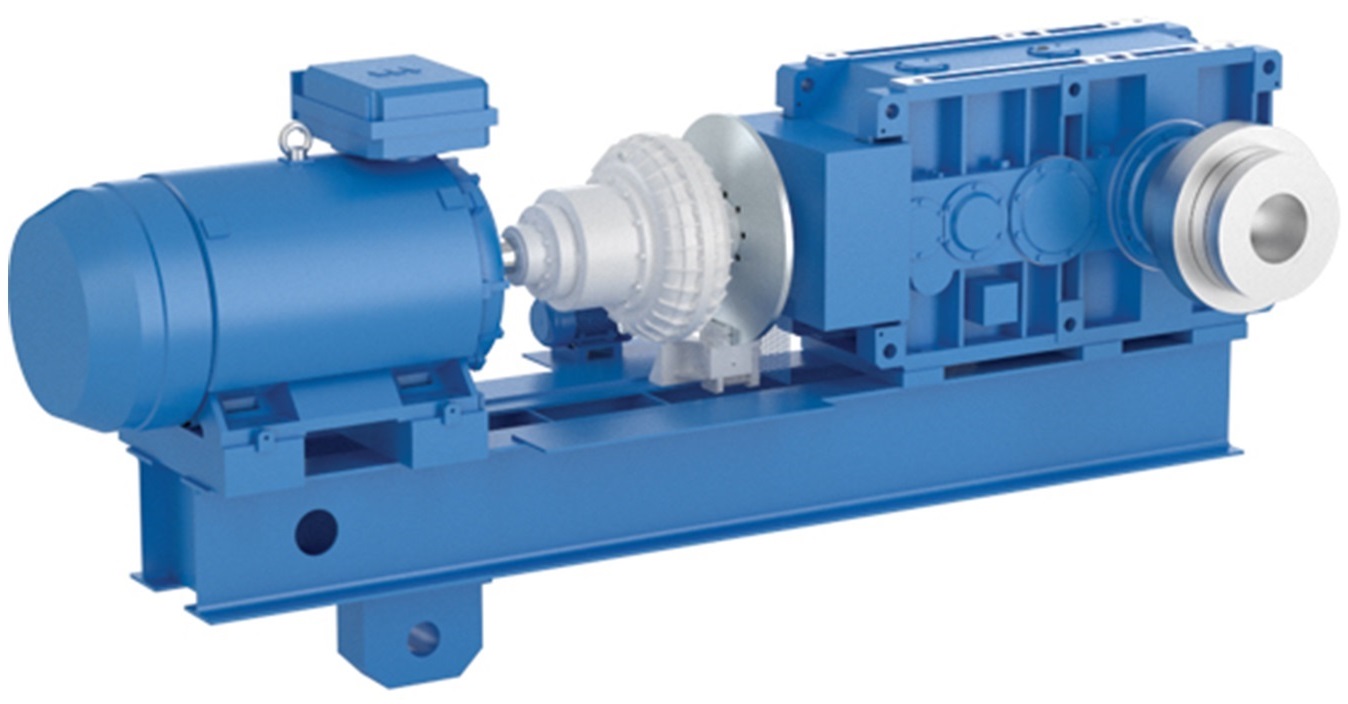

Helical bevel gear reducers are typically used in applications that require a high degree of precision and accuracy. They can be used for high-torque applications such as conveyor systems, pumps, and motors, and are also used in industrial equipment such as printing presses and machine tools.

The main advantages of helical bevel gear reducers are their efficient and quiet operation, long life, and low maintenance. They are also very reliable, as they are designed with multiple lubrication points and high-quality materials. Helical bevel gear reducers can be tailored to the specific requirements of each application, allowing for a wide range of speed and torque combinations.

Helical bevel gear reducers are often used in combination with other gear reducers, such as planetary or worm gear reducers. This allows for a more efficient and cost-effective solution, as the multiple gear reducers can be customized to meet the needs of the system.

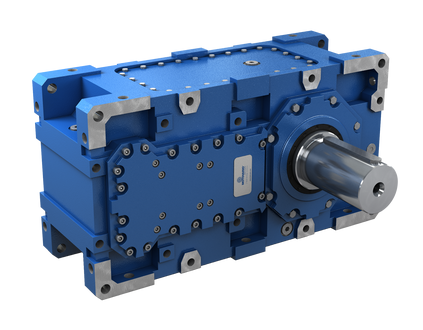

Right-angle gear reducers are available in both standard and custom configurations. Standard configurations are off-the-shelf products that require no customization and are typically used in standard applications, while custom configurations are designed to meet specific application requirements and may require special materials or specific gear ratios

In conclusion, right-angle gear reducers are essential components in many industrial and manufacturing applications as their compact design, reliability, and versatility make them ideal for a wide range of applications where space is limited and high torque is required. The high gear reduction ratio of these reducers allows for a significant decrease in speed while concurrently increasing torque output, leading to improved power transmission efficiency and prolonged equipment service life.